In many industries, foam formation disrupts production, slows efficiency, and can even cause costly shutdowns. Poor foam control also affects product quality, appearance, and performance.

Effective foam management is essential for stable, high-quality manufacturing. While defoamers and antifoaming agents are often confused, they serve different roles—understanding them helps you choose the right solution.

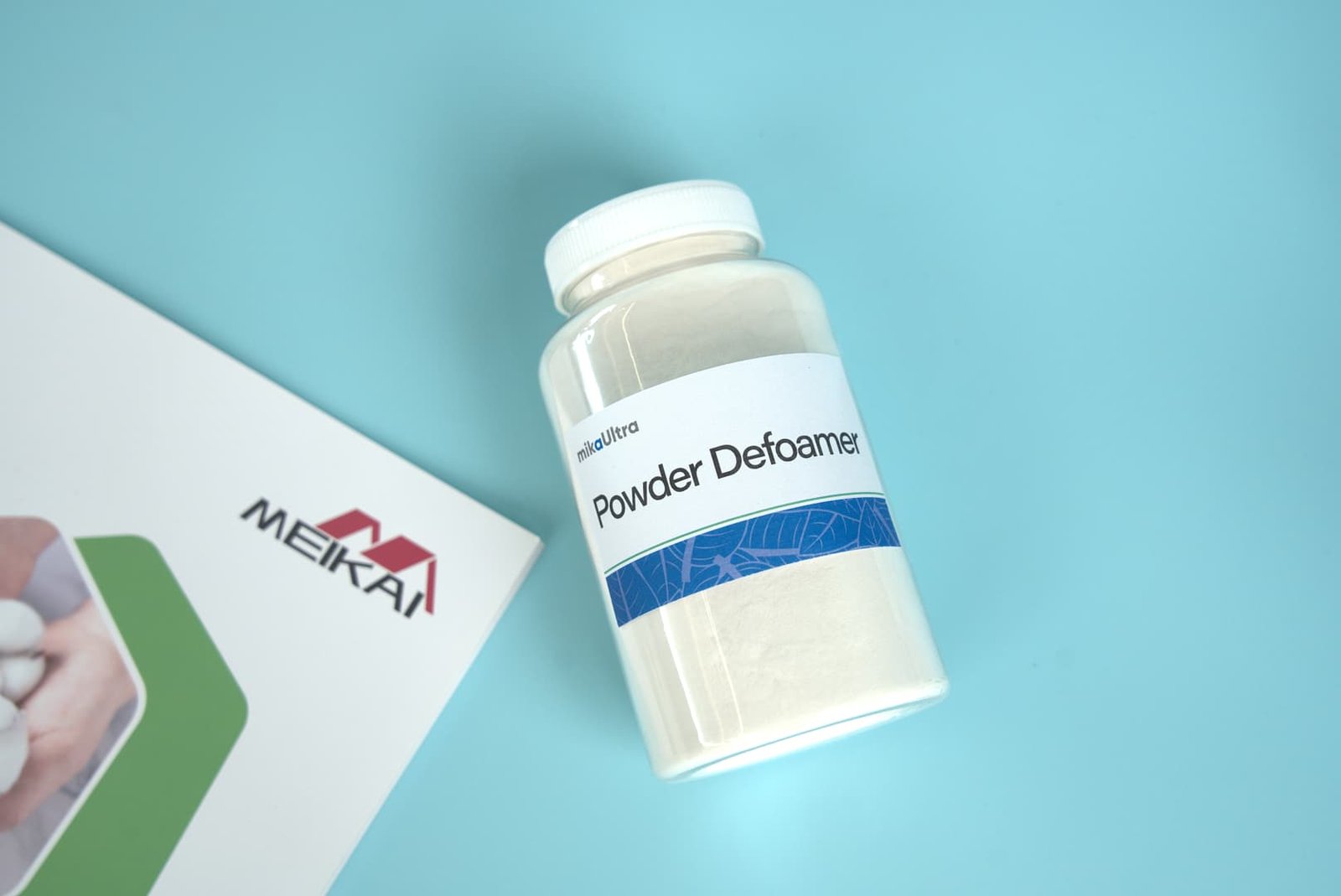

Mikazone offers high-quality defoamers designed for diverse industries. Our advanced formulations ensure fast foam suppression, long-term stability, and smooth, efficient production.

What Is an Antifoaming Agent?

An antifoaming agent is a chemical additive engineered to prevent foam from forming in the first place. These agents modify the surface characteristics of a liquid system so gas bubbles have a harder time nucleating, growing, and stabilizing into visible foam. Unlike defoamers, which act after foam has already appeared, antifoams take a forward-looking approach by intervening at or before the onset of foam.

The primary objective of an antifoaming agent is to suppress foam initiation. They achieve this by lowering the liquid's surface tension, disrupting bubble nucleation, or triggering rapid collapse of nascent foam before it becomes problematic.

How Does Antifoam Work?

To grasp how antifoams operate, it helps to revisit how foam forms. Foam consists of gas trapped within a liquid film. For foam to develop, two conditions must be present: continuous gas dispersion where the liquid must spread gas evenly, creating a population of small bubbles, and a stable liquid film that must form a structure sturdy enough to resist rupture, thereby trapping gas within the bubbles.

Antifoams intervene by disturbing the gas–liquid interface. They address the two critical conditions through several core mechanisms:

Preventing Gas Molecule Clustering

Antifoams position themselves at the gas–liquid interface and adjust surface tension, making it harder for tiny gas bubbles to coalesce into larger bubbles.

Destabilizing Microbubbles

If small bubbles do appear, antifoams weaken their thin liquid film, causing them to collapse before they can grow into visible foam.

Absorbing Available Gas

Some components in antifoams bind free gas molecules, reducing the pool available for bubble formation.

Neutralizing Foam-Stabilizing Substances

Proteins or surfactants in liquids can stabilize bubbles. Antifoams can displace these stabilizers or break them down, undermining the foam's structural integrity.

Through these steps, antifoams either prevent foam from forming or provoke rapid collapse of existing foam. Unlike defoamers, which are reactive once foam is present, antifoams are designed to act proactively.

What Is a Defoamer?

Defoamers are used to eliminate foam that has already formed. While antifoams prevent foam from arising, defoamers destabilize the structure of the bubbles and promote rupture or coalescence, allowing foam to dissipate quickly. The primary objective of a defoamer is to reduce or remove foam as soon as it interferes with processes.

Defoamers are indispensable when foam is actively present and slowing operations. They work by lowering the local surface tension within the foam, which destabilizes bubble walls and leads to rupture, coalescence, and eventual disappearance of the foam blanket.

How Does Defoamer Work?

The central action of a defoamer is the rapid lowering of the surface tension inside the foam. This destabilizes bubble walls, triggering rupture and collapse. The effectiveness of a defoamer hinges on two key parameters:

Spreading Coefficient

The defoamer's ability to spread across the surface of the foam's liquid film. A positive spreading coefficient ensures the defoamer can effectively cover the foam surface, creating the conditions necessary for destabilization.

Entry Coefficient

The defoamer's ability to penetrate the foam's liquid film. A positive entry coefficient allows the defoamer droplets to breach the foam structure and begin the process of bubble collapse from within.

For optimal performance, both coefficients must be positive. The droplets must first breach the foam film (entry) and then spread across its surface (spreading), thinning the film until it ruptures.

Types and Key Components of Defoamer and Antifoam

Both defoamers and antifoams rely on a core set of ingredients. The principal components typically include active ingredients such as silicone-based compounds (for example, polydimethylsiloxane), polyethers, various oils, water-based formulations, and hydrophobic particles like modified silica. Emulsifiers are used to distribute the active ingredients evenly for greater efficiency, while carriers such as mineral oil or water help stabilize and deliver the actives.

Common Classes of Defoamers and Antifoams

Polyether-Based Defoams

Effective in high-temperature environments and in systems with strong acid or alkali conditions. Their thermal stability makes them ideal for demanding industrial processes.

Fatty Alcohol Defoams

Versatile and widely used across a range of aqueous systems. These formulations offer reliable performance in moderate conditions at competitive costs.

Silicone Defoamers

Known for high efficiency and persistent action in demanding applications. Their superior spreading characteristics enable excellent foam control even at low dosages.

Non-Silicone Defoams

Cost-efficient options for general industrial use. These formulations provide reliable foam control without the premium associated with silicone-based products.

Mineral Oil-Based Defoamers

Suitable for a broad spectrum of industrial processes. Their compatibility with various systems makes them a versatile choice for many applications.

In practice, formulating a successful defoamer or antifoam often involves selecting a balance of actives, emulsifiers, and carriers to match the chemistry, temperature, pH, and shear environment of the target process. Compatibility with materials in contact with the product is also essential to avoid contamination or worsened foaming.

Applications and Industries

Defoamers and antifoams find utility across a wide spectrum of industries. Each application presents its own foam challenges and process constraints, but the underlying principles of foam control remain consistent.

Wastewater Treatment

Foam control in aeration tanks and clarifiers helps prevent process shutdowns, reduces energy consumption, and minimizes blockages in pipelines and equipment. In these high-oxygen, variable-pH environments, choosing robust polymer-based or silicone-based formulations that resist degradation is critical.

Pulp and Paper

Foaming can occur during pulping, dilution, and coating steps. Effective defoaming safeguards fiber distribution, enhances dewatering performance, and improves surface smoothness in coatings and finishes.

Textiles and Dyeing

Dye baths and finishing lines can generate unstable foams that lead to color variability and defects in fabric surfaces. Targeted antifoams help maintain consistent dye uptake and uniform finishing.

Paints, Coatings, and Inks

Foam control is essential for pigment dispersion, viscosity control, and air entrapment prevention. Improper foam management can result in pinholes, color variation, and surface defects in coatings and printed products.

Food and Beverage

Fermentation, cleaning-in-place (CIP), and processing lines can produce foams that interfere with product quality and sanitation. Food-grade defoamers and antifoams, formulated to meet regulatory requirements, are crucial here.

Pharmaceuticals

Foam can affect particle size, impurity removal, and filtration steps during formulation and manufacturing. Controlled defoaming and antifoaming help preserve product purity and process consistency.

Metalworking

Foam in cutting fluids, coolants, and cleaning baths can hinder heat transfer and surface quality. Efficient defoaming reduces downtime and improves plating uniformity in downstream steps.

Chemical Manufacturing

Foam management supports stable reactions, mixing, distillation, and downstream processing in petrochemical refining, latex production, and specialty chemical manufacturing.

A note on suitability: In highly sensitive sectors (e.g., beverages, pharmaceuticals, or food-contact applications), selecting food-grade or directive-compliant formulations is essential. Likewise, in high-temperature or highly acidic/alkaline environments, choosing the right class of defoamer or antifoam—polyether-based, mineral oil-based, or silicone-based—determines not just foam control, but long-term equipment integrity and process reliability.

Why Choose Mikazone for Your Defoamer and Antifoam Solutions?

At Mikazone, we recognize foam control as a pivotal driver of process efficiency, product quality, and overall profitability. As a leading producer of high-performance defoamers and antifoams, Mikazone brings breadth of experience, rigorous scientific rigor, and a comprehensive product portfolio designed to meet the toughest foam challenges.

Expertise and Innovation

With deep experience in construction materials and industrial chemicals, Mikazone partners with customers to optimize their processes. Our R&D organization continually refines foam-control chemistries, leveraging the latest insights in surface science, colloids, and process engineering to deliver reliable, repeatable performance.

Learn More →Broad Product Range

Mikazone offers a versatile lineup of defoamers and antifoams engineered for diverse industrial needs. Whether your system operates at elevated temperatures, under vigorous agitation, or within demanding chemical environments, Mikazone has a solution that fits. Our products are curated to address the most common foaming mechanisms encountered in real-world plants.

Learn More →Custom Solutions

We understand that each process is unique. Our technical team collaborates with customers to tailor defoamer and antifoam formulations to specific operating windows, materials compatibility, and regulatory requirements. This collaborative approach yields solutions that are not only effective but also durable over time.

Learn More →Quality and Consistency

Quality drives consistency. Mikazone's manufacturing and QA processes are designed to deliver dependable performance batch after batch. We source high-grade raw materials and apply stringent controls to ensure that your foam-control performance remains stable across operations and over product lifecycles.

Learn More →Safety and Sustainability

We are committed to safe, sustainable solutions. Mikazone formulations are designed to minimize environmental impact, prioritize worker safety, and comply with global environmental standards. Our products are developed with an eye toward high performance while reducing risk in your processes and supply chain.

Learn More →Dedicated Technical Support

Beyond product delivery, Mikazone offers ongoing technical support, application guidance, and troubleshooting. Our specialists partner with your engineering teams to optimize foam-control performance, troubleshoot anomalies, and sustain peak process efficiency.

Ready to Solve Your Foam Problems?

Reach out to Mikazone for expert consultations, customized defoamer and antifoam formulations, and complimentary samples.

Contact Mikazone TodayOur team of specialists is ready to help you identify the ideal product to meet your precise foam-control requirements and to design a testing plan that simulates your real operating conditions.